By Jeffrey Margolis, Managing Director, Illinois Science and Technology Coalition

Haven Allen, Manufacturing Strategy Manager, World Business Chicago

Illinois has a strong legacy as a state of makers and builders. Product development and manufacturing that advance key industries have been a crux of Illinois’ economy from the advent of the assembly line. More recently, Illinois has been the birthplace of devices like the cellular phone, the LED light, and needle-less IV. Technology and innovation are needed to restore the state’s manufacturing eminence, launch new products that can be produced locally, and grow high-skill, high-wage jobs in industries like heavy equipment, consumer electronics, aerospace, and agribusiness.

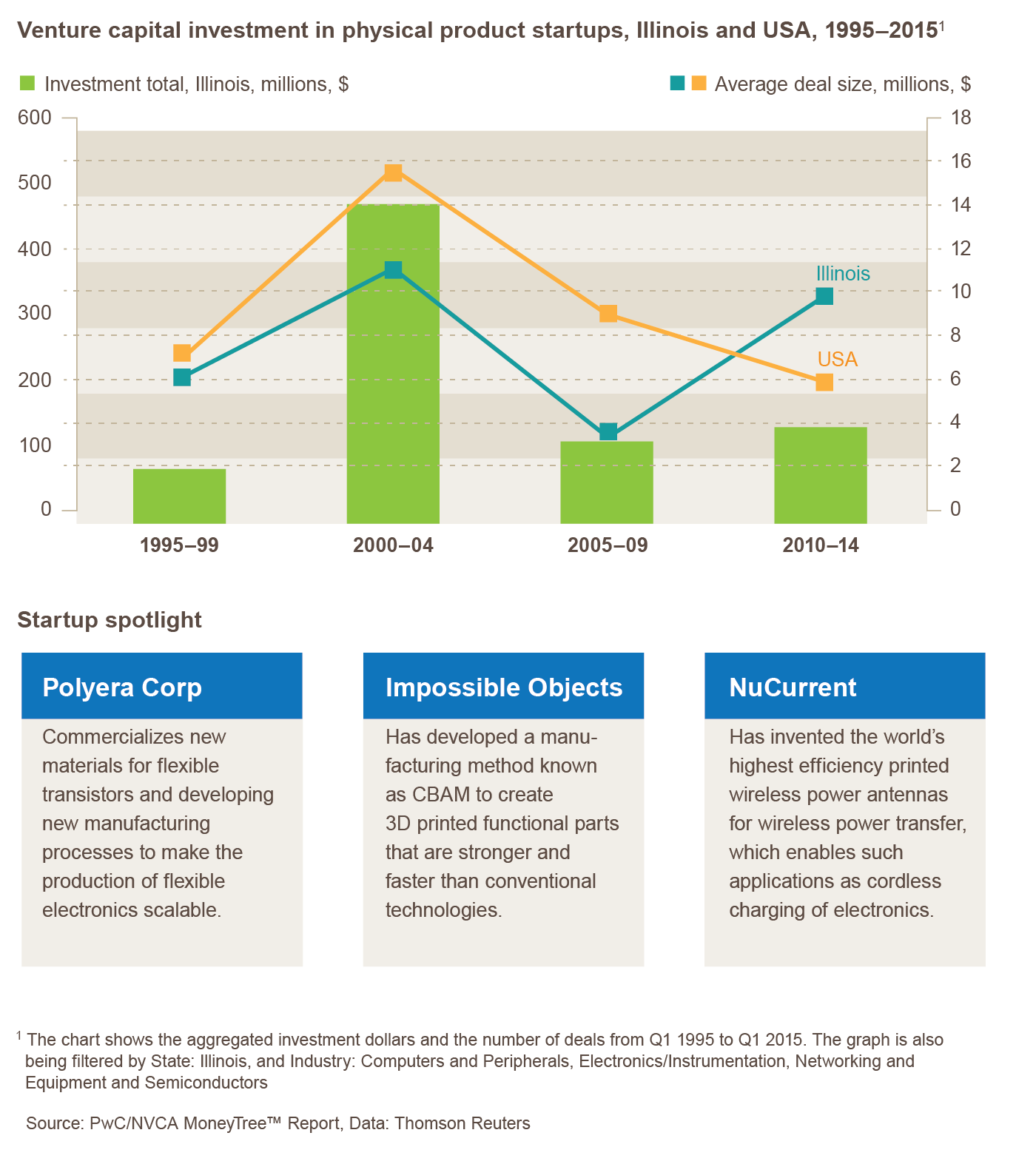

Physical product innovation requires additional infrastructure needs and longer timelines than digital and software technologies. For this reason, venture investment in Illinois-based companies in this space has been limited with just over $855 million in total funding in the 20 years between 1995-2015; but it is accelerating (see infographic). Thanks to lower capital needs for physical product development as a result of 3D printing and the dramatically decreased costs of sensor components, it is now possible to rapidly scale new device products and attract risk capital.

To harness this growth, a number of public and private initiatives are launching across the state to further democratize access to the materials, equipment, education, and expertise needed to launch new hardware ventures. A growing network of regional and university-based physical product innovation centers in Illinois are helping to mitigate the capital, design and production barriers by providing affordable and flexible access to the equipment needed to prototype new devices.

Collaboration and connectivity between these spaces has already helped create success stories that highlight the potential for the Illinois hardware community to serve as a new job engine in Chicago and beyond. Companies like NuCurrent – which creates the world’s most efficient antennas for wireless power charging – demonstrate how connecting the region’s university, hardware development, and manufacturing resources can help physical product companies grow locally. Launched through the Northwestern University NUvention course, NuCurrent has flourished at Catalyze, whose members have raised $18 million and sold more than $28 million in products in little over a year.

Building a network that strengthens product development and harnesses innovators to solve challenges that hinder manufacturing competitiveness, will make Illinois the hub for advanced manufacturing. That is the goal of the Manufacturing Innovation Hub (mHub) – an initiative launched through World Business Chicago’s Advisory Council for Chicagoland Manufacturing technology working group, chaired by ISTC. Just as 1871 and MATTER do for the digital and health tech communities, mHub will provide a focal point for the hardware and advanced manufacturing community.

Imagine hundreds of engineers, designers, business talent, and university students working hand-in-hand with Illinois’ manufacturers. This ecosystem and a broader network that links universities and regional incubators will create a unique reciprocal value for entrepreneurs and manufacturers: Manufacturers help hardware startups create products that can be made at scale and cost, saving significant time and cost in the prototyping process, and then provide a supply network to manufacture these new products locally. Physical product innovators, in turn, can help solve R&D challenges that companies cannot address in-house.

The mHub builds on and joins a network of maker spaces and fabrication labs. This network will link its targeted solution approach with the “grand challenges” applied research of the Digital Manufacturing and Design Innovation Institute (DMDII) to grow an ecosystem that enables manufacturers to develop technical solutions to their product and process challenges. In doing so, mHub will extend the impact and increase the already realized success of other efforts across the state. NIU’s EIGERlab helped Rockford area high school students create a 3D printed prosthetic hand for a local nine year old born without fingers. This low cost solution enables her to change sizes more frequently than with high-cost options. Gramavox, housed at 1871, brings an old-fashion aesthetic to sound technologies including a Bluetooth-enabled gramophone. Last week, the startup launched a Kickstarter campaign to raise funds to build out manufacturing capability for its floating record player.

In the long term, cultivating the maker movement also provides hands-on ways to get kids – and even adults – motivated to pursue science, technology, engineering, and math (STEM) careers. The South Metropolitan Higher Education Consortium’s SouthWorks MakerLab Network and the Museum of Science and Industry’s Wanger Family Fab Lab build design and manufacturing skills through experiential learning. The resulting talent pool is ultimately the source for new hardware ventures and the skills needed to keep Illinois manufacturers competitive in global markets.

Given Illinois’ bench strength in hardware, software, and manufacturing, the state is positioned to lead innovation and production in exploding markets like Internet of Things wearables, and robotics. With DMDII now open on Goose Island, Illinois stands to be the place where industry-driven innovation in sensor technology, data analytics, and connected devices are commercialized – a potential multi-billion industry itself. The mHub network offers the talent and infrastructure to capture this value to drive local economic development.

Watch and Listen

How digital manufacturing transforms the manufacturing process

Learn

- Maker space meetups in Chicago

- Using the Chicago Innovation Exchange (CIE) fab lab

- How to become a member of Catalyze Chicago

- Learn product development at Windy City Lab

- Discover the fab lab at the Chicago Harold Washington Public Library

More News

- Jerry Roper, ISTC Board Member and champion of Illinois business, passes away

- Motorola Mobility Foundation announces hackathon on July 17 in honor of 25th anniversary of the Americans with Disabilities Act

- Small Business Administration (SBA) and EnterpriseWorks Chicago join forces for the Chicago SBIR Road Tour

- University of Illinois awarded $3.1M to develop all-terrain rovers for high-throughput field phenotyping

- AKHAN semiconductor opens manufacturing facility in Gurnee in proximity to Argonne and College of Lake County

Illinois Innovation Network Featured Resource:

Illinois Innovation Network Featured Resource: Each month, the Illinois Science and Technology Coalition features a service or resource available to innovators and entrepreneurs in the state of Illinois on the Illinois Innovation Network. To learn more and add your resource to the Network, click here.

The TTS Global Initiative annual summit held in Chicago July 20-21 is the only interactive summit meeting bringing together decision-makers and KOLs from all the stakeholder groups in early-stage life sciences; from university, hospital and clinic technology offices and start-up companies, to patient organizations and foundations, to early-stage and late-stage investors, and senior representatives from pharma and industry. Continue reading at Illinois Innovation Network

The TTS Global Initiative annual summit held in Chicago July 20-21 is the only interactive summit meeting bringing together decision-makers and KOLs from all the stakeholder groups in early-stage life sciences; from university, hospital and clinic technology offices and start-up companies, to patient organizations and foundations, to early-stage and late-stage investors, and senior representatives from pharma and industry. Continue reading at Illinois Innovation Network![]()